- Products

- Resources

- Support

- About Us

- Blog

- Contact

- Online Store

SUPPORT

Nitrogen Generators for Sample Preparation:

Everything You Need To Know

Table of Contents

Jump to section:

- What is a laboratory nitrogen generator and when is one used?

- Common ways labs obtain nitrogen

- Which nitrogen generator technology is right for me?

- The true cost of tank-based nitrogen solutions

- Is it cheaper to generate my own nitrogen?

- All the headaches you can save by adding on-site nitrogen generation

- Why nitrogen is ideal for drying samples

- Installing a nitrogen generation system for sample preparation

What is a laboratory nitrogen generator and when is one used?

A laboratory nitrogen generator is a machine that is able to separate nitrogen molecules from the air around it by using a compressed air source. By removing the vast majority of oxygen molecules and other impurities from an air source, these machines are able to produce high purity or ultra-high purity nitrogen gas needed to run a variety of different laboratory applications and instruments.

There are many applications that require a lab to use a nitrogen gas generator, with LC-MS, GC, ICP, ELSD, and sample preparation/blowdown evaporation being the most common. Each application will have specific nitrogen requirements (flow rate, purity level, etc.) which will determine the exact type of N2 generator needed by the lab.

|

Application |

Flow Rate |

Purity Level |

|

LC-MS |

High (30 to 40 L/min) |

Moderate to high (~97-99%) |

|

GC |

Low (under 1 L/min) |

Ultra-high (>99.999%) |

|

ICP |

Low to Moderate (<5 L/min) |

Ultra-high (>99.999%) |

|

ELSD |

Low to Moderate (<5 L/min) |

High (~98-99%) |

|

Sample Prep/Blowdown Evaporation |

Moderate to High (5 to 40 L/min) |

Low to Moderate (<98%) |

N2 gas generators aren’t the only way labs are able to obtain nitrogen. Let’s get into some other common sources, and discuss when they may be a better fit.

Common ways labs obtain nitrogen

Although nitrogen generators are a must-have for many laboratories, there are some instances where they just don’t make sense. Some labs may have a nitrogen consumption rate that is just too high for a generator to meet. On the other hand, some may require such a low amount of gas that the purchase of a generator can’t be justified.

So what are the common nitrogen gas sources for labs and who should be using each?

1. Nitrogen Tanks, Cylinders, or Dewars

Ordering nitrogen gas from a third party vendor and having it delivered to your facility in tanks, cylinders, or Dewars is a great option for labs who have a very low or sporadic need for nitrogen. It’s a convenient way to get a small amount of N2 gas which may only be needed for a single project, without committing to the purchase of a new piece of equipment.

Ordering nitrogen gas from a third party vendor and having it delivered to your facility in tanks, cylinders, or Dewars is a great option for labs who have a very low or sporadic need for nitrogen. It’s a convenient way to get a small amount of N2 gas which may only be needed for a single project, without committing to the purchase of a new piece of equipment.

2. Built-In Nitrogen Source

Some large analytical or manufacturing companies have full nitrogen systems installed directly in their building which are able to supply gas to an entire lab or labs, depending on the size. This allows lab techs to have a constant supply of N2 gas piped directly to their fume hood or workstation. Due to the cost and space requirements, this is only a worthwhile investment for large laboratories with very high nitrogen consumption requirements.

Some large analytical or manufacturing companies have full nitrogen systems installed directly in their building which are able to supply gas to an entire lab or labs, depending on the size. This allows lab techs to have a constant supply of N2 gas piped directly to their fume hood or workstation. Due to the cost and space requirements, this is only a worthwhile investment for large laboratories with very high nitrogen consumption requirements.

3. Nitrogen Generator

Investing in a nitrogen gas generator is an ideal choice for labs who fall in the middle of options 1 and 2. If your application requires N2 on a regular basis, but doesn’t necessitate a building-wide gas source, a generator is the perfect accommodation. Most are completely plug-and-play, meaning once it’s set up, you can simply turn it on or off as needed, without any reconfiguration.

Investing in a nitrogen gas generator is an ideal choice for labs who fall in the middle of options 1 and 2. If your application requires N2 on a regular basis, but doesn’t necessitate a building-wide gas source, a generator is the perfect accommodation. Most are completely plug-and-play, meaning once it’s set up, you can simply turn it on or off as needed, without any reconfiguration.

Which nitrogen generator technology is right for me?

There are two common types of N2 generators, differentiated by the way they separate nitrogen molecules from the air. There are membrane-based generators and PSA generators.

1. Membrane-Based

The technology behind membrane-based nitrogen generators is…you guessed it…a membrane. This type of generator contains a series of narrow, semi-permeable fibers located in a porous membrane. As compressed air is passed through, some gas molecules such as oxygen, carbon dioxide and water vapor are able to permeate the fibers quite easily and are vented off, while nitrogen molecules pass through much slower. This results in a high purity nitrogen stream (95-99% purity) from the membrane outlet.

The technology behind membrane-based nitrogen generators is…you guessed it…a membrane. This type of generator contains a series of narrow, semi-permeable fibers located in a porous membrane. As compressed air is passed through, some gas molecules such as oxygen, carbon dioxide and water vapor are able to permeate the fibers quite easily and are vented off, while nitrogen molecules pass through much slower. This results in a high purity nitrogen stream (95-99% purity) from the membrane outlet.

Continue reading here for a more in-depth explanation on how membrane nitrogen generators work.

Organomation’s NITRO-GEN is a popular membrane-based N2 generator for sample preparation that is used by analytical laboratories worldwide. Producing up to 20 L/min at up to 99% purity, this lightweight generator is suitable for those using blowdown evaporation for solvent concentration. Find out how the NITRO-GEN supplies high purity nitrogen for a sample concentrator.

2. PSA (Pressure Swing Adsorption) Technology

%20side.jpeg?width=319&height=319&name=NITRO-GEN+%20(NA1935)%20side.jpeg) PSA generators work by using two columns of tightly packed material called Carbon Molecular Sieve (CMS). Compressed air will pass through one CMS column, which will adsorb all oxygen, water vapor and other molecules, while allowing nitrogen to pass through and be stored in an accumulation tank. Once one sieve becomes saturated, compressed air will be diverted to the second CMS column, allowing the first one to depressurize, releasing all adsorbed impurities through an outlet. This process repeats over and over, leaving behind N2 gas with a 98-99.999% purity.

PSA generators work by using two columns of tightly packed material called Carbon Molecular Sieve (CMS). Compressed air will pass through one CMS column, which will adsorb all oxygen, water vapor and other molecules, while allowing nitrogen to pass through and be stored in an accumulation tank. Once one sieve becomes saturated, compressed air will be diverted to the second CMS column, allowing the first one to depressurize, releasing all adsorbed impurities through an outlet. This process repeats over and over, leaving behind N2 gas with a 98-99.999% purity.

Continue reading here for a more in-depth explanation on how PSA technology works.

As this technology tends to produce a slightly higher purity and flow rate than with membranes, PSA generators are a great choice for both sample preparation and LC-MS applications. The NITRO-GEN+ is an affordable PSA generation solution that is able to produce up to 35 L/min, meeting all your sample prep and analytical needs. Find out how the NITRO-GEN+ can be your laboratory’s all-in-one nitrogen generation solution.

For more information on the pros and cons of each generator type, go to "which generator technology is right for me?"

The true cost of tank-based nitrogen solutions

Although seen as the popular and “traditional” nitrogen generation solution by many, the process of purchasing N2 tanks is quite pricey, especially for those consuming gas on a weekly or daily basis. There are many associated costs with tank-based solutions including the cost of the actual nitrogen, tank rentals, and required delivery. Let’s take a look at how much one analytical lab could be spending on tanks in just one year.

** This example uses estimated pricing. Your actual costs may vary.

A typical nitrogen tank costs around $50. It’s also common for vendors to charge a monthly rental fee, which is often around $20 each month, per individual cylinder. On top of that, you’ll be charged for delivery – for this example, let’s say the lab orders their tanks locally and it only costs them $25 per delivery.

Now, let’s estimate the nitrogen consumption for this particular lab. Let’s say they need 30 L/min of nitrogen for 4 hours a day, 5 days a week. That equals 36,000 liters of nitrogen per week, or about 5 cylinders. Over the course of a whole year, that’s nearing 2 million liters and over 250 nitrogen cylinders.

In just one year, this lab would be spending over $18,000 in nitrogen tanks alone! For most, this just isn’t feasible.

Is it cheaper to generate my own nitrogen?

Acquiring a generator and producing your own nitrogen is a sure way to cut back on these extensive costs. Laboratory generators that are able to produce moderate flow rates and purity levels can range anywhere from $5,000 to $40,000. This one-time payment plus any required maintenance are the only things you have to take care of. No more worrying about rental costs, delivery costs, or wondering why the price of tanks has suddenly increased.

Depending on a lab’s nitrogen consumption levels, the payback period on a N2 generator could be as little as 1-3 years.

Determine how long it would take your lab to pay off a generator by using this simple nitrogen generator payback period calculator, and see how much you could be saving.

All the headaches you can save by adding on-site nitrogen generation

Now that you’ve seen how much money a generator can save you compared to tanks, let’s dive deeper into all the headaches nitrogen generators can save you to determine if generating nitrogen in your lab is worthwhile.

1. No need to purchase, store, or handle nitrogen cylinders

Not only are tank-based nitrogen solutions expensive, they are also quite time-consuming and labor-intensive. Having to dedicate a closet or a corner of the lab to store extra tanks or remembering to order more when you’re running low are just minor inconveniences. Not to mention, high-pressure tanks can be a danger to those handling them.

2. Never run out of nitrogen again

With tanks, you always have to make sure you have enough for the day or week ahead. Running out of nitrogen unexpectedly can cause major hiccups in your workflow, and can even ruin the analysis/test you’re currently working on. With a nitrogen generator, you’ll always have a steady stream of high purity nitrogen available when you need it.

3. Never pause your operation to replace N2 tanks

Let’s say you’re in the middle of concentrating down some analytical samples using a nitrogen dryer, and your nitrogen tank has just run out. You’re forced to stop the evaporation process, disconnect the empty tank, move it aside, bring in a new tank, recalibrate it, and hook it up to the evaporator. All the while your samples are sitting in the open air with the risk of oxidizing or otherwise becoming contaminated. With the constant gas supply a N2 generator provides, you’ll never have to worry about this happening.

4. Reduce waste and be more eco-friendly

Utilizing a laboratory generator can help reduce your carbon footprint by eliminating the need to participate in tank exchanges and having nitrogen cylinders shipped to and from your laboratory. Since you’re generating nitrogen from the air around you, you’ll never require a refill or replacement.

Learn even more ways a nitrogen gas generator enhances sample preparation and improves laboratory workflows.

Why nitrogen is ideal for drying samples

Labs using nitrogen blowdown evaporation, a common sample preparation step before analysis, are major drivers of the nitrogen generation market. Have you ever wondered why nitrogen is used to dry down excess solvent? It’s actually quite simple.

1. It has the fastest evaporation rate.

Studies have proven that nitrogen gas yields the fastest evaporation rates compared to other inert gasses. Evaporation rate is dependent on the humidity of the atmosphere. So what’s the most effective way to reduce humidity levels? – by purging the atmosphere with nitrogen, aka nitrogen blowdown evaporation.

2. It poses minimal risks to samples & lab techs.

Dry nitrogen is considered an inert gas, meaning it is chemically inactive. Unlike compressed air that contains high levels of oxygen and other impurities, dry nitrogen will not deteriorate your samples in any way during the evaporation process. N2 is also non-flammable, meaning it will not increase the risk of a chemical combustion, which is especially important when working with other flammable or reactive solvents.

3. It's affordable.

Installing a nitrogen generation system for sample preparation

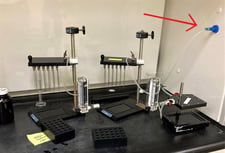

Nitrogen generators have been used and trusted for sample concentration for years, specifically in conjunction with the TurboVap, N-EVAP, and RapidVap. Once you've narrowed down your options, it's important to also take a look at the key considerations for installing a generator in your lab.

To conclude, let's take a look at some real-life examples of laboratories who have integrated a nitrogen generator into their sample preparation workflow to see just how impactful it can be.

Baylor University - Robbins College of Health and Human Services

Temple University - McKenzie Environmental Engineering Research Group

Congratulations! You’re now an expert on laboratory nitrogen generators. Incorporating one into your lab is easy – first determine your nitrogen requirements, research generators that can meet these requirements, and select the best option for you. Once it’s set up in your lab, you’re done! You now have 24/7 on-demand nitrogen gas for whenever you need it.

If you have any questions or would like assistance with your nitrogen generator journey, please reach out to sales@organomation.com or call our team at 978-838-7300.

→ Discover: How gas cylinders can disrupt gas chromatography sample preparation

Get Exclusive Lab Deals Straight to Your Inbox

Limited-time offers, special pricing, and practical lab insights in our newsletter

Contact Help Support

If you need support from one of our technicians, please fill out our Contact Help Support form and we will respond as quickly as possible! For all other enquiries, please use this general contact form.

USA 888.838.7300

Other 978.838.7300

978.838.2786